To install a power steering pump, first locate the old pump and remove it by disconnecting the hoses and bolts. Then, place the new pump in position and secure it by reattaching the hoses and bolts.

The Importance Of A Power Steering Pump

Why a Power Steering Pump is Crucial for Vehicle Performance

A power steering pump is an essential component of a vehicle’s steering system. It plays a crucial role in ensuring smooth and effortless steering, enhancing overall driving experience and vehicle performance. With its ability to multiply the steering effort applied by the driver, the power steering pump provides the necessary force to turn the wheels and maneuver the vehicle with ease.

Improved Steering Ability: The power steering pump assists in overcoming the resistance between the tires and the road. It enables the driver to turn the wheels effortlessly, especially at low speeds or when making tight maneuvers. With the power steering pump in place, navigating through crowded city streets or parking in narrow spaces becomes a breeze.

Enhanced Control: A power steering pump ensures precise control over the vehicle’s direction. By reducing the steering effort required from the driver, it allows for quick and accurate steering inputs. This is particularly beneficial when driving on winding roads or during emergency situations where swift and precise steering response can make a difference in avoiding collisions.

Reduced Driver Fatigue: Manual steering can be physically demanding, especially when driving for extended periods or handling heavy vehicles. The power steering pump alleviates the strain on the driver by providing hydraulic assistance, resulting in reduced fatigue and enhanced comfort during long journeys. It allows drivers to focus more on the road ahead, promoting safer driving practices.

Preservation of Vehicle Components: A properly functioning power steering pump helps protect other steering components from undue stress and premature wear. Without the assistance of a power steering pump, the excessive force exerted on the steering system can lead to damage or failure of crucial components, such as the steering rack and pinion or tie rods. By ensuring proper fluid circulation and pressure, the power steering pump helps prolong the lifespan of these vital parts.

| Benefits of a Power Steering Pump |

|---|

| Smooth and effortless steering |

| Improved control and maneuverability |

| Reduced driver fatigue |

| Preservation of steering components |

In conclusion, the power steering pump is not merely a convenience feature, but a critical component that significantly contributes to the overall performance and safety of a vehicle. Its ability to enhance steering ability, provide better control, reduce driver fatigue, and protect other steering components makes it an invaluable addition to any vehicle’s steering system.

Signs Of A Faulty Power Steering Pump

If you’ve been experiencing problems with your car’s power steering, there’s a good chance that your power steering pump is to blame. The power steering pump plays a crucial role in making your steering feel smooth and effortless, but over time it can wear out or develop faults. In this section, we’ll explore the common signs that indicate a failing power steering pump.

Identifying common symptoms of a failing power steering pump

When it comes to diagnosing a faulty power steering pump, there are a few key symptoms to look out for. By being aware of these signs, you can catch the problem early and save yourself from costly repairs down the line.

Here are the most common symptoms that indicate a failing power steering pump:

Strange noises and steering difficulties

If you start hearing strange noises when turning the steering wheel, such as squealing, whining, or groaning sounds, it’s a strong indication that your power steering pump is on the blink. These sounds usually occur due to a lack of fluid or a worn-out pump. Additionally, if you notice that it takes more effort than usual to turn the wheel, or if the wheel feels jerky or unresponsive, it’s likely that your power steering pump is not functioning properly.

Leaking fluid and impaired power assist

Another red flag for a faulty power steering pump is fluid leakage. If you notice puddles or drips of power steering fluid under your car, it’s a clear sign that there’s a leak in the system. This leakage not only leads to a loss of fluid, but it can also result in impaired power assist, making it harder to steer your vehicle. Keep an eye out for low fluid levels in the power steering reservoir, as it may indicate a leaking pump.

It’s important to address these power steering pump issues promptly, as a failing pump can not only compromise your steering control but also lead to further damage to the power steering system overall. If you notice any of these symptoms, it’s recommended to consult a professional mechanic to accurately diagnose the problem and recommend the appropriate course of action.

By being vigilant and aware of the signs of a faulty power steering pump, you can ensure the longevity and optimal performance of your power steering system.

Preparing For Installation

Before you begin installing a power steering pump, it’s essential to properly prepare yourself and gather all the necessary tools and equipment. Additionally, it’s crucial to identify the correct power steering pump for your specific vehicle and diagnose the cause of pump failure. By following these steps, you’ll have a smooth and successful installation process.

Gathering necessary tools and equipment

To ensure a successful installation, you’ll need to gather the following tools and equipment:

- Socket set

- Wrenches (various sizes)

- Power steering pump pulley removal tool

- Power steering fluid

- Shop towels or rags

- Jack and jack stands

Having all these tools and equipment ready will save you time during the installation process. Make sure to double-check that you have everything before beginning.

Identifying the correct power steering pump for your vehicle

Identifying the correct power steering pump for your vehicle is crucial to ensure compatibility and proper functioning. Here’s how you can do it:

- Refer to your vehicle’s owner manual or consult a reliable online resource to find the exact specifications and part number for the power steering pump.

- Alternatively, you can contact your vehicle manufacturer or a local auto parts store and provide them with your vehicle’s make, model, and year to help you identify the correct power steering pump.

- Ensure that the power steering pump you purchase matches the specifications and part number recommended for your vehicle.

By identifying the correct power steering pump for your vehicle, you can avoid any compatibility issues and ensure proper installation.

Diagnosing the cause of pump failure

Before installing a new power steering pump, it’s important to diagnose the cause of the pump failure. This step will help you identify any underlying issues that may have led to the pump’s failure and prevent future problems. Follow these steps to diagnose the cause of pump failure:

- Inspect the power steering fluid for contamination, such as debris or metal particles. This could indicate internal pump damage.

- Check the power steering hoses for leaks or damage. A faulty hose could lead to pump failure.

- Examine the power steering belt for signs of wear or improper tension. A loose or worn-out belt can strain the pump and cause it to fail.

- Listen for any unusual noises coming from the power steering system, such as whining or squealing. These noises could indicate a pump or belt problem.

- If you’re unsure about the cause of pump failure, it’s recommended to consult a professional mechanic who can provide a thorough diagnosis.

By diagnosing the cause of pump failure, you can address any underlying issues and ensure a successful installation.

Removing The Old Power Steering Pump

Removing the old power steering pump is a crucial step in replacing it with a new one. This process requires a few key tasks, including draining the power steering fluid, loosening and removing the serpentine belt, and disconnecting hoses and fittings. By following these steps, you can ensure a smooth and successful installation of your new power steering pump.

Draining the Power Steering Fluid

Before removing the old power steering pump, it is essential to drain the power steering fluid. To accomplish this, locate the power steering fluid reservoir typically located on the engine compartment. Place a drain pan underneath the reservoir to catch the fluid.

To drain the fluid, remove the reservoir cap, and use a siphoning tool or turkey baster to extract as much fluid as possible. Ensure that the drain pan is positioned to catch any additional fluid that may spill during the process.

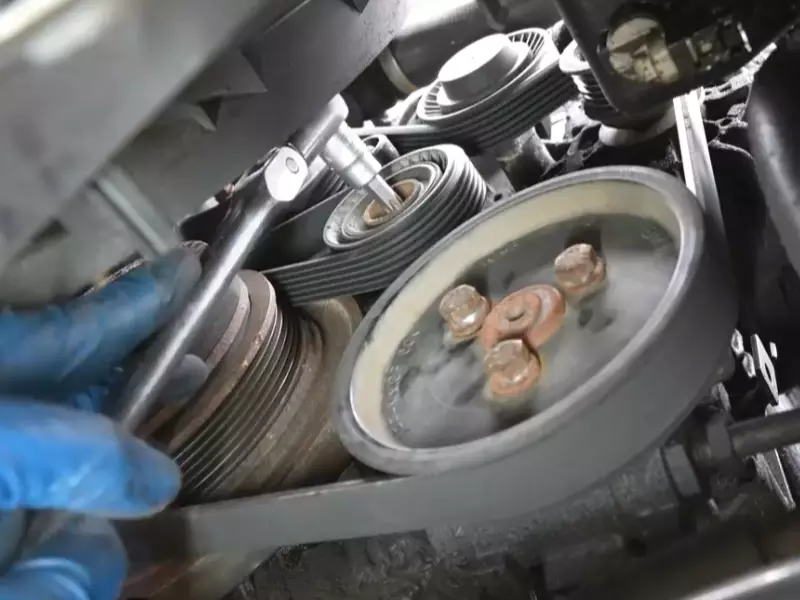

Loosening and Removing the Serpentine Belt

The next step in removing the old power steering pump is loosening and removing the serpentine belt. This belt is responsible for driving multiple engine components, including the power steering pump.

Begin by identifying the belt tensioner, usually located near the front of the engine. Use a wrench or a breaker bar to rotate the tensioner and release the tension on the belt. Carefully slide the belt off the pulleys and set it aside.

Disconnecting Hoses and Fittings

With the power steering fluid drained and the serpentine belt removed, it is now time to disconnect the hoses and fittings from the old power steering pump. Depending on your vehicle’s make and model, you may need specific tools such as a flare nut wrench or adjustable wrench to loosen the fittings.

Start by identifying the pressure and return lines connected to the pump. Loosen the fittings using the appropriate wrench and be prepared for any residual fluid to drain. Next, locate any other hoses or fittings that may be attached to the pump and disconnect them.

Remember to label or mark each hose or fitting as you disconnect them to ensure correct reinstallation later. Keep track of any brackets or clips that may be securing the hoses or fittings to the pump as well.

Once all the hoses and fittings are disconnected, you can now safely remove the old power steering pump from the vehicle.

Now that you have successfully completed the process of removing the old power steering pump, you are one step closer to installing a new one. Follow the next steps in the installation process to ensure a seamless and efficient replacement.

Table:

| Steps | Description |

|---|---|

| Draining the Power Steering Fluid | Locate the power steering fluid reservoir and drain the fluid using a siphoning tool or turkey baster. |

| Loosening and Removing the Serpentine Belt | Identify the belt tensioner, release the tension, and slide off the serpentine belt. |

| Disconnecting Hoses and Fittings | Use appropriate wrenches to loosen and disconnect the pressure and return lines, as well as any other hoses or fittings. |

| Removing the Old Power Steering Pump | With all hoses and fittings disconnected, remove the old power steering pump from the vehicle. |

Installing The New Power Steering Pump

After removing the old power steering pump, it’s time to install the new one. Follow these steps to ensure a proper installation.

Attaching hoses and fittings

The first step in installing the new power steering pump is to attach the hoses and fittings. Start by connecting the high-pressure hose to the pump, making sure it is securely fastened. Then, attach the low-pressure return hose to the appropriate fitting. Be sure to tighten both connections to prevent any leaks.

Aligning the pump pulley with the belt

Once the hoses and fittings are attached, it’s important to align the pump pulley with the belt. This ensures that the pump will properly engage and function while driving. To align the pulley, rotate it until the grooves match up with the belt. Rotating the pulley may require some force, so be patient and careful during this step.

Tightening and securing all connections

After aligning the pump pulley, it’s important to tighten and secure all the connections. Start by double-checking the hose and fitting connections, making sure they are tight and secure. Next, tighten the mounting bolts or brackets that hold the power steering pump in place. This will help ensure that the pump remains stable and doesn’t vibrate or move while in use.

Finally, go through each connection and give it a final check to ensure everything is tight and secure. Ensuring that all connections are properly tightened will help prevent any leaks or malfunctions down the road.

Installing a new power steering pump may sound daunting, but by following these steps and taking your time, you can successfully complete the task. Remember to always refer to your vehicle’s specific manual for any additional instructions or specifications. With a properly installed power steering pump, you’ll be back on the road with smoother steering in no time.

Refilling And Testing The System

When installing a power steering pump, the last step is refilling and testing the system. This is an essential part of the process as it ensures that your power steering system is working properly and is free from any air bubbles that could affect its performance. In this section, we will cover how to add new power steering fluid, bleed the system to remove air bubbles, and test for proper functioning.

Adding new power steering fluid

The first step in refilling the power steering system is adding new power steering fluid. Refer to your vehicle’s manual to determine the appropriate type of power steering fluid to use. Here’s a step-by-step guide:

- Locate the power steering fluid reservoir, which is usually near the engine.

- Remove the cap from the reservoir.

- Carefully pour the new power steering fluid into the reservoir, using a funnel if necessary to avoid spilling.

- Fill the reservoir to the recommended level indicated on the dipstick or reservoir itself.

- Once filled, securely replace the cap on the reservoir.

Bleeding the system to remove air bubbles

After adding new power steering fluid, it’s essential to bleed the system to remove any trapped air bubbles. Here’s how to do it:

- Start the engine and let it idle.

- Slowly turn the steering wheel from lock to lock several times.

- This action will force any air bubbles to rise to the top of the system.

- Check the power steering fluid level and add more if necessary.

- Repeat the process of turning the steering wheel from lock to lock until there are no visible air bubbles in the power steering fluid.

Testing for proper functioning

Once you have refilled the system and removed any air bubbles, it’s time to test for proper functioning of the power steering. Follow these steps:

- Start the engine and let it idle.

- Turn the steering wheel in both directions to ensure it moves smoothly without any hesitation or resistance.

- Listen for any abnormal noises coming from the power steering system, such as squealing or grinding.

- Check for any fluid leaks around the power steering pump and hoses.

- If everything appears to be in order, take your vehicle for a test drive to ensure the power steering is functioning properly while driving.

By following these steps to refill and test your power steering system, you can ensure that it is functioning correctly and avoid any future issues. Remember to consult your vehicle’s manual for any specific instructions or considerations based on the make and model of your car.

Troubleshooting Common Installation Issues

Are you experiencing issues after installing a power steering pump? Don’t worry, troubleshooting common installation issues can help you get your power steering system back on track. In this section, we will discuss two common problems that may arise: air in the system and leaking connections. We will also provide step-by-step instructions on how to eliminate air from the system and fix leaking connections. So, let’s get started!

Air in the System: How to Eliminate It

If you notice that there is air in your power steering system, it can cause poor performance and noisy operation. To eliminate air from the system, follow these steps:

- Start by locating the power steering reservoir. It is usually a small plastic or metal container near the power steering pump. Refer to your vehicle’s manual if you are unsure about its location.

- Check the fluid level in the reservoir. If it is low, fill it up with the recommended power steering fluid. Make sure not to overfill.

- Bleed the system by turning the steering wheel from lock to lock several times. This will help remove any trapped air bubbles. Remember to do this with the engine off.

- Once you have completed the bleeding process, start the engine and check the fluid level again. Top it up if necessary.

Leaking Connections: How to Fix Them

Leaking connections can cause power steering fluid to leak and affect the performance of your power steering system. Here’s how you can fix leaking connections:

- Inspect all the connections in the power steering system, including hoses, fittings, and seals. Look for signs of leakage such as fluid stains or drips.

- If you find a leaking connection, use a wrench or pliers to tighten it. Be careful not to overtighten, as it may cause damage.

- If tightening the connection doesn’t solve the issue, you may need to replace the faulty component. Refer to your vehicle’s manual or consult a professional for guidance.

By following these troubleshooting steps, you can resolve common installation issues with your power steering pump. Remember to always refer to your vehicle’s manual and exercise caution when working with your power steering system. Now, you should be able to enjoy smooth steering and enhanced power assist once again!

Frequently Asked Questions On How To Install A Power Steering Pump

Can I Replace Power Steering Pump Myself?

Yes, you can replace a power steering pump yourself. Just make sure to follow a step-by-step guide and have the necessary tools. Take caution and follow safety guidelines to avoid any damage or injury.

Is It Difficult To Replace A Power Steering Pump?

Replacing a power steering pump can be challenging. It requires technical knowledge and skills. It is recommended to seek professional help for a safe and accurate replacement.

How Many Hours Does It Take To Replace A Power Steering Pump?

It typically takes around 2 to 4 hours to replace a power steering pump. Keep in mind that the exact time may vary depending on the vehicle’s make and model, as well as the experience of the technician.

How Do You Change A Power Steering Pump?

To change a power steering pump, follow these steps:

- Disconnect the negative battery cable.

- Remove the drive belt that connects to the pump.

- Take off the hoses connected to the pump.

- Unbolt and remove the old pump from its mounting bracket.

- Install the new pump, reconnect the hoses and belt, and then reconnect the battery cable.

Conclusion

Installing a power steering pump is a crucial task that requires attention to detail and proper technique. By following the step-by-step guide outlined in this blog post, you can successfully install a power steering pump and ensure smooth steering functionality in your vehicle.

Remember to gather the necessary tools, take your time, and seek professional assistance if needed. With the right knowledge and approach, you can easily tackle this task and enjoy a hassle-free driving experience.