To install load resistors for LED lights, you need to connect the resistor in parallel with the LED light source. This ensures that the proper load is maintained and prevents issues like hyper flashing or error messages.

LED lights have become a popular choice due to their energy efficiency and longer lifespan. However, they often require load resistors to function correctly. These resistors help balance the electrical load and prevent problems like fast flashing or error messages on the dashboard.

We will guide you on how to install load resistors for LED lights, ensuring a seamless and efficient lighting experience. So let’s dive in and learn the simple steps to install these resistors and enjoy the benefits of LED lighting without any complications.

Understanding Load Resistors For LED Lights

In this blog post, we will explore the topic of load resistors for LED lights, specifically focusing on how to install them. One crucial aspect of installing LED lights is understanding load resistors and their importance in ensuring the proper functioning of LED light systems. This post will delve into the significance, functionality, and installation process of load resistors, providing you with the necessary knowledge to implement them effectively. So, let’s dive in and explore the world of load resistors for LED lights!

Importance of Load Resistors in LED Light Installations

Load resistors play a crucial role in LED light installations. When you switch from traditional incandescent bulbs to LEDs, you may encounter a common issue known as hyper flashing or rapid blinking of turn signals. This occurs because LEDs have a much lower power draw compared to their incandescent counterparts. The vehicle’s computer system detects this lower power draw as a fault and triggers rapid blinking to indicate a bulb failure.

To combat this issue, load resistors are introduced into the LED light system. These resistors mimic the power draw of the incandescent bulbs, fooling the vehicle’s computer system into detecting normal functioning. By providing the required load, load resistors effectively eliminate hyper flashing and ensure smooth and consistent blinking of LED turn signals.

How Load Resistors Function in LED Light Systems

Load resistors work by dissipating excess voltage as heat, which restores the power draw to a level that closely matches that of traditional incandescent bulbs. They achieve this functionality through their resistance properties. The resistance within the load resistor creates a voltage drop across it, effectively limiting the amount of current flowing through the LED circuit.

By limiting the current, load resistors prevent the vehicle’s computer system from detecting a fault and triggering rapid blinking. Furthermore, load resistors help maintain the correct load on the LED circuit, ensuring that other electronic components within the system, such as flasher relays, function optimally.

It’s important to note that load resistors generate heat as they dissipate excess voltage. Therefore, proper installation is crucial to ensure they are adequately cooled and positioned away from sensitive components or flammable materials. Consult the manufacturer’s guidelines for installation instructions specific to your LED light system and vehicle model.

If you are concerned about the added heat generated by load resistors, you can also consider using LED bulbs that incorporate built-in resistors. These bulbs are designed to mimic the power draw of traditional bulbs without the need for additional load resistors. However, it’s essential to select bulbs that are compatible with your specific vehicle model and LED light system.

In conclusion, understanding load resistors and their significance in LED light installations is vital for ensuring a properly functioning system. The importance of load resistors lies in their ability to eliminate hyperflashing, restore power draw, and maintain the correct load within the LED circuit. By dissipating excess voltage as heat, load resistors effectively mimic the behavior of traditional incandescent bulbs, fooling the vehicle’s computer system and preventing false alerts. With proper installation and consideration of alternative options, you can experience the benefits of LED lights without encountering any issues related to hyperflashing.

Steps To Install Load Resistors For LED Lights

In order to ensure the smooth functioning of your LED lights, it is important to install load resistors correctly. These resistors help balance the electrical load and prevent issues such as hyper flashing or error codes. Below are the steps to install load resistors for LED lights, along with the necessary tools and equipment.

Gathering the Necessary Tools and Equipment

Before you begin the installation process, gather the following tools and equipment:

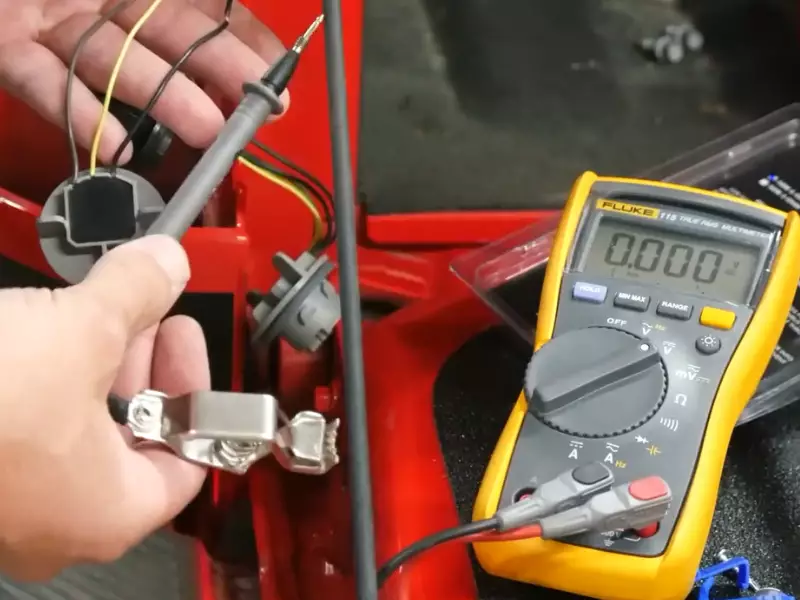

- Multimeter

- Wire cutters

- Wire strippers

- Soldering iron

- Heat shrink tubing

- Electrical tape

- Load resistors

- Electrical connectors

Identifying the Appropriate Load Resistor for Your LED Lights

Choosing the right load resistor is crucial for a successful installation. To identify the appropriate load resistor for your LED lights, consider the power and wattage of the lights. Most load resistors are designed to handle a specific wattage range. Consult the manufacturer’s specifications or seek professional advice if you are unsure about the wattage of your LED lights.

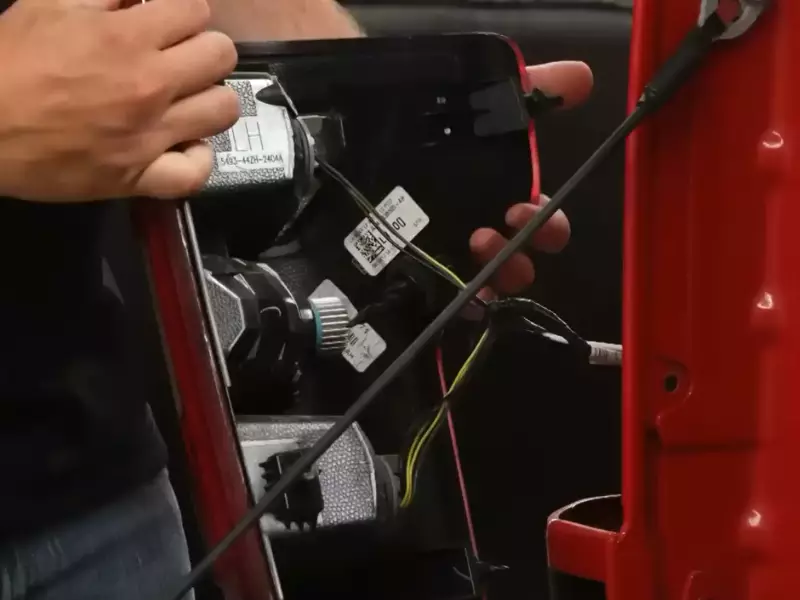

Locating the Correct Position for Installing the Load Resistor

The load resistor should be installed as close to the LED light as possible. This helps dissipate the heat generated by the resistor effectively. Choose a location that allows for easy access and does not interfere with any other components in the car. It is recommended to mount the resistor on a metal surface, as this helps with heat dissipation.

Connecting the Load Resistor to the LED Light Circuit

Follow these steps to connect the load resistor to the LED light circuit:

- Using the wire cutters, cut the power wire of the LED light circuit that needs the load resistor.

- Strip the ends of the cut wire using the wire strippers.

- Heat shrink tubing can be used to insulate the cut ends of the wire. Slide the tubing over the wire and use a heat source to shrink it, ensuring proper insulation.

- Connect one end of the load resistor to one stripped end of the wire, using electrical connectors or by soldering them together.

- Connect the other end of the load resistor to the other stripped end of the wire in the same manner.

- Insulate the connected wires and load resistor using electrical tape or heat shrink tubing.

Once you have completed these steps, test the LED lights to ensure they are functioning properly. If there are any issues, double-check the connections and consult a professional if necessary.

By following these steps, you can successfully install load resistors for LED lights and enjoy their benefits without any complications. Remember to always prioritize safety and consult a professional if you are unsure about any step in the process.

Troubleshooting Common Issues With Load Resistors For Led Lights

When it comes to installing load resistors for LED lights, it’s not uncommon to encounter some common issues that may require troubleshooting. In this section, we will discuss the most prevalent problems and provide solutions to help you resolve them effectively.

Overheating and Burnt Load Resistors

Overheating and burnt load resistors can be a headache when dealing with LED light installations. This issue typically occurs when there is excessive power flowing through the resistors, causing them to get hotter than they are designed to handle. To prevent this problem, it’s important to ensure that the load resistors you are using are compatible with the power rating of the LED lights.

If you are experiencing overheating and burnt load resistors, here are some troubleshooting steps you can take:

- Check the power rating of the LED lights and compare it to the load resistors’ specifications. Ensure that the load resistors can handle the power being supplied.

- Inspect the wiring connections to make sure they are secure and not causing any resistance or short circuits.

- If necessary, consider replacing the load resistors with ones that have a higher power rating to better match the power requirements of the LED lights.

Load Resistor Compatibility Issues

Compatibility issues with load resistors can arise when using them with certain LED lights or vehicles. These problems may manifest as flickering lights, error codes on the dashboard, or lights not functioning as expected. It’s important to address these compatibility issues to ensure proper operation and reliability of the LED lights.

To troubleshoot load resistor compatibility issues, you can follow these steps:

- Verify that the load resistors you are using are specifically designed for the type of LED lights or vehicle you have. Some resistors are model-specific and may not work properly with other applications.

- Double-check the wiring connections to ensure there are no loose or faulty connections causing compatibility issues.

- If the problem persists, consult the manufacturer’s documentation or customer support for guidance on resolving compatibility issues.

Load Resistor Placement Problems

The placement of load resistors plays a crucial role in their effectiveness. Placing them incorrectly can lead to dim or uneven lighting, improper load balancing, or interference with other electrical components. It’s essential to ensure proper load resistor placement to achieve optimal performance.

If you are facing load resistor placement problems, consider the following troubleshooting tips:

- Refer to the installation instructions provided by the manufacturer for the recommended placement of the load resistors. Follow these guidelines carefully to ensure the best results.

- Verify that the load resistors are securely installed and not vibrating or moving around. Loose or improper placement can cause connection issues and degrade their performance.

- Inspect the surrounding area for potential sources of heat or exposure to moisture, as these factors can impact the performance and lifespan of load resistors.

By addressing these common issues and troubleshooting them effectively, you can ensure smooth and efficient operation of LED lights in your vehicle or any other application. Don’t hesitate to seek support from the manufacturer or a professional if you encounter challenges beyond your troubleshooting capabilities.

Resolving Overheating And Burnt Load Resistors

Are your load resistors for LED lights constantly overheating and burning out? Don’t worry, you’re not alone. Many DIY enthusiasts face this frustrating issue. In this article, we will explore effective techniques to resolve overheating and burnt load resistors. By following these methods, you can ensure the longevity of your load resistors and maintain optimal performance for your LED lights. Let’s delve into the details.

Identifying Excessive Heat as the Cause of Burnt Load Resistors

One way to identify excessive heat as the cause of burnt load resistors is by frequently monitoring their temperature during operation. If you notice that the load resistors become extremely hot to the touch, it is a clear indication that they are overheating and at risk of getting damaged. Additionally, if you notice burn marks or discoloration on the load resistors, it is a tell-tale sign of overheating and potential failure.

To prevent further damage, it is essential to take immediate action when you realize your load resistors are getting excessively hot. Thankfully, there are practical steps you can take to address this issue.

Adjusting Load Resistor Placement to Improve Heat Dissipation

One effective technique to reduce the overheating of load resistors is by strategically adjusting their placement. Proper placement allows for better heat dissipation and prevents the concentration of heat in a specific area. Consider these tips for optimum heat management:

- Securely fasten the load resistors to a metal surface, such as the vehicle’s body or heat sink, that can act as a heat sink to draw away excess heat.

- Ensure that the load resistors are positioned away from any heat-sensitive components in your vehicle to prevent potential damage.

- Provide sufficient space around the resistors to allow for adequate airflow, which aids in heat dissipation. Avoid overcrowding the resistors, as it can hinder proper cooling.

By implementing these placement adjustments, you can significantly improve the heat dissipation effect and minimize the risk of burnt load resistors.

Considering Alternatives to Traditional Load Resistors

While load resistors have been the go-to solution for resolving electronic issues related to LED lights, there are alternative options available. These alternatives provide effective load balancing while offering superior heat dissipation capabilities. Some popular alternatives to traditional load resistors include:

| Alternative | Advantages |

|---|---|

| LED Anti-Flicker Canbus Decoders |

|

| Electronic Flasher Relays |

|

| LED Load Equalizers |

|

In conclusion, preventing overheating and burnt load resistors is crucial for LED light installations. By keeping a close eye on temperature, adjusting load resistor placement, and exploring alternative options, you can overcome this common issue and enjoy uninterrupted performance from your LED lights. Remember to consider the unique needs of your specific LED system and choose the most suitable solution from these methods.

Addressing Load Resistor Compatibility Issues

When it comes to installing LED lights, addressing compatibility issues is crucial to ensure smooth operation and optimal performance. One common compatibility challenge arises when integrating load resistors with LED light controllers. In this article, we will delve into the relationship between load resistors and LED light controllers, how to check for compatible resistance values, and the steps to resolve any incompatibility issues with load resistors.

Understanding the Relationship Between Load Resistors and LED Light Controllers

In order to correctly diagnose and address compatibility issues with load resistors, it’s essential to understand the relationship between these resistors and LED light controllers. Load resistors are used to mimic the power draw of a traditional incandescent bulb, providing the necessary resistance to avoid hyper-flashing or error messages in the vehicle’s electrical system.

Checking the Compatible Load Resistor Resistance Value

Before installing load resistors, it’s important to verify the compatible resistance value required by the LED light controller. This information can usually be found in the product specifications or the manufacturer’s documentation. To check the compatible resistance value:

- Consult the LED light controller’s manual or product specifications.

- Locate the specified resistance range or value.

- Ensure that the load resistor’s resistance falls within this specified range.

Resolving Incompatibility Issues with Load Resistors

If you discover that the load resistor’s resistance is not compatible with the LED light controller, there are several steps you can take to address the issue:

- Obtain a load resistor with the correct resistance value: If the resistance of the current load resistor does not match the LED light controller’s specifications, you will need to replace it with a load resistor that has the appropriate resistance value.

- Install multiple load resistors in parallel: If the resistance value required by the LED light controller exceeds the capacity of a single load resistor, you can install multiple resistors in parallel to achieve the desired resistance.

- Consult a professional: If you are unsure about the compatibility of load resistors or the appropriate solution for your specific situation, it is recommended to consult a professional technician or an expert in automotive electronics.

Resolving load resistor compatibility issues is crucial to ensure the proper functioning of LED lights. By understanding the relationship between load resistors and LED light controllers, checking for compatible resistance values, and taking the necessary steps to address any incompatibility, you can install load resistors confidently and enjoy the benefits of LED lighting in your vehicle.

Troubleshooting Load Resistor Placement Problems

Installing load resistors for LED lights is an essential step to ensure that your lighting system functions optimally and avoids any potential issues. However, it is not uncommon to encounter placement problems when installing load resistors. In this section, we will discuss some common challenges and provide solutions to help you troubleshoot and overcome these obstacles.

Locating Optimal Positions for Efficient Load Resistor Installation

When it comes to installing load resistors for LED lights, identifying the optimal positions is crucial for efficient performance. Here are some guidelines to assist you:

- Locate the nearest grounding point: Connecting the load resistor to the nearest grounding point will help dissipate excess current effectively.

- Place the load resistor away from heat-sensitive components: Heat generated by load resistors can potentially damage nearby cables or sensitive electronic parts. Ensuring sufficient distance can prevent such issues.

- Secure the load resistor in a cool and well-ventilated area: Heat dissipation is essential for the load resistor to function properly. Mounting it in a location with good airflow and away from potential heat sources is recommended.

Overcoming Space Constraints and Cable Length Limitations

Installing load resistors can present challenges, especially when faced with limited space or cable length limitations. Here are some solutions to help you overcome these obstacles:

- Consider using compact load resistors: Compact load resistors are specifically designed for installations in tight spaces. These resistors offer a smaller footprint while still providing the necessary load to stabilize the LED lights.

- Extend cable length if necessary: In cases where cable length limitations are a concern, extending the cables using appropriate connectors or cable extenders can help ensure proper positioning of the load resistor.

- Utilize alternative mounting options: If space constraints make it difficult to mount the load resistor in the conventional manner, explore alternative mounting methods such as adhesive tapes or cable ties. These options can provide flexibility in placement.

Ensuring Proper Insulation and Protection of the Load Resistor

Proper insulation and protection of the load resistor are vital to prevent any potential damage or malfunctions. Follow these steps to ensure the load resistor is well-insulated and protected:

- Apply heat shrink tubing or electrical tape: Covering the load resistor with heat shrink tubing or electrical tape provides insulation and protects it from external elements.

- Maintain a safe distance from flammable materials: To avoid any fire hazards, ensure that the load resistor is installed at a safe distance from flammable materials or sources of ignition.

- Double-check for secure connections: Confirm that all connections are secure and properly tightened to prevent any accidental disconnection or damage to the load resistor.

Do’S And Don’Ts Of Installing Load Resistors For LED Lights

Installing load resistors for LED lights is an essential step to ensure the proper functionality and longevity of your lighting system. However, it is important to follow certain guidelines to avoid any potential issues. In this article, we will discuss the do’s and don’ts of installing load resistors for LED lights, ensuring a hassle-free experience.

Do: Follow the Manufacturer’s Instructions for Specific Load Resistor Models

When it comes to installing load resistors for LED lights, it is crucial to carefully follow the manufacturer’s instructions. Each load resistor model may have unique specifications and requirements, and following the instructions will help you install the resistor correctly and prevent any compatibility or performance issues.

Do: Test the LED Light System After Installing the Load Resistor

Once you have successfully installed the load resistor, it is important to test the LED light system to ensure everything is functioning properly. Turn on the lights and observe if there are any flickering, dimming, or abnormal behavior. This step will help you identify any issues early on and make necessary adjustments if needed.

Don’t: Overload the Load Resistor by Connecting Too Many LED Lights

While load resistors are designed to handle a specific load, it is essential not to overload them by connecting too many LED lights. Overloading can lead to overheating, reduced lifespan of the resistor, or even damage to the LED lights. Make sure to check the load resistor’s maximum load capacity and connect an appropriate number of LED lights accordingly.

Don’t: Damage the Load Resistor or LED Lights During Installation

During the installation process, it is important to handle the load resistor and LED lights with care to prevent any accidental damage. Mishandling or applying excessive force can result in physical damage, affecting the overall performance and lifespan. Take your time, be gentle, and double-check the connections to ensure a secure and damage-free installation.

Following these do’s and don’ts when installing load resistors for LED lights will help you achieve optimal results and avoid potential issues. Remember to adhere to the manufacturer’s instructions, test the system post-installation, avoid overloading the resistor, and handle the components with care. By doing so, you can enjoy the benefits of a properly functioning and long-lasting LED lighting system.

Frequently Asked Questions For How To Install Load Resistors For LED Lights

Do I Need A Load Resistor For Led Lights?

Yes, load resistors are required for LED lights to ensure proper functioning. They help balance the electrical load and prevent issues like hyperflash or error messages. Installing load resistors is crucial to maintain the performance and longevity of LED lights in your vehicle or home.

Where Does A Led Load Resistor Go?

A LED load resistor should be connected in parallel with the LED bulb to stabilize the electrical current and prevent hyper-flashing.

Can You Use Load Resistors For Led Headlights?

Yes, load resistors can be used for LED headlights to prevent hyper-flashing due to the lower power draw of LED bulbs compared to conventional halogen bulbs. Load resistors mimic the power draw of halogen bulbs, ensuring proper functioning of the vehicle’s electrical system.

How Big Of A Resistor Do I Need For An Led?

For an LED, the size of the resistor you need depends on the LED’s forward voltage and current rating. Use Ohm’s law to calculate the resistor value. Divide the difference between the power supply voltage and the forward voltage by the forward current to determine the resistor value in ohms.

Conclusion

Installing load resistors for LED lights is a crucial step in ensuring their proper functioning and longevity. By following the step-by-step guide provided in this blog post, you can confidently tackle this task and enjoy the benefits of your LED lights.

Remember, load resistors help eliminate issues like hyperflashing or bulb-out warnings, making your lights more reliable and efficient. So, don’t hesitate to add load resistors to your LED lighting setup and enhance your overall lighting experience.